- Ponuka

- KAN-therm ultraLINE System

- System KAN-therm ultraPRESS

- System KAN-therm PP

- System KAN-therm Steel

- System KAN-therm Inox

- System KAN-therm Inox Sprinkler

- System KAN-therm Groove

- System KAN-therm Copper

- System KAN-therm Tacker

- System KAN-therm Profil

- System KAN-therm Rail

- System KAN-therm TBS

- Systém KAN-therm WALL – mokrá metoda Novinka!!!

- System KAN-therm WALL - сух метод Новост!!!

- System KAN-therm Football

- KAN-therm InoxFlow

- KAN-therm Slim & Slim+ skrinky

- Na stiahnutie

- Záruka kvality

- O nás

- O nás

- Filozofie firmy

- Výroba

- Events

- Noviny

- A new KAN production plant has opened!

- Newsletter coming out soon!

- SYSTEM KAN-therm at Aquatech China 2017

- Changes in the KAN-therm 6in1 System catalogue

- KAN-therm in Jordanki

- Ďakujeme za návštevu Aquatech China 2017

- Nové inštalačné skrinky SYSTÉMU KAN-therm

- Pozrite si naše nové návodné video aplikácie KAN Smart Control

- Slovenský katalóg je teraz k dispozícii!

- KAN-therm certified quality

- Amazon v Seredi

- Become Underfloor Heating KAN-therm System Champion

- Navštívte KAN-therm na ISH India

- Visit KAN at ISH Frankfurt 2019

- Skontrolujte riešenia KAN-therm pre rodinné domy

- System KAN-therm v salóne PORSCHE

- KAN-therm s novým certifikátom QB

- System KAN-therm Groove

- ZRM. Estetika ruka v ruke s funkčnosťou.

- Nové lisovačky v ponuke KAN-therm

- Montáž System KAN-therm Groove

- KAN-therm Multi-system

- Inštalácie...neoplatí sa šetriť na nich!

- Novinka – KAN Rozdeľovač z nerezovej ocele

- Aquatherm Praha 2020

- Správne bezpečnostné opatrenia, rovnaká účinnosť

- New products on offer

- History

- Noviny

- Fairs

- Kontakty

- Slovak / Slovak

-

- Belarusian | bieloruský

- Bosnian | bosnianska

- Bulgarian | bulharský

- Croatian | chorvátsky

- Czech | český

- English | anglicky

- Estonian | estónsky

- Finnish | fínsky

- French | francúzsky

- German | nemecký

- Hungarian | maďarský

- Latvian | lotyšský

- Lithuanian | litovský

- Polish | poľský

- Romanian | rumunský

- Russian | ruský

- Serbian | srbský

- Slovak | slovenský

- Slovenian | slovinčina

- Swedish | Švedsko

- Ukrainian | ukrajinský

- Norwegian | nórsky

- Belarusian | bieloruský

The selected pipe should be cut perpendicularly to the axis to the required length by means of plastic pipe cutters. It is not allowed to use other tools or scissors which are faulty (blunt or chipped).

The selected pipe should be cut perpendicularly to the axis to the required length by means of plastic pipe cutters. It is not allowed to use other tools or scissors which are faulty (blunt or chipped).

Put the sleeve onto the pipe. Symmetric structure allows for both-side installation.

Put the sleeve onto the pipe. Symmetric structure allows for both-side installation.

Pipe expander should be equipped with a head suitable for the type of the pipe and its diameter. Insert the expanding head fully into the pipe until it stops, axially into the pipe end. Expansion of the pipe should be carried out in two phases: I – initial full expansion of the pipe, in full range of the tool stroke, turn the expander by 45° after expansion, II - final full expansion of the pipe, in full range of the tool stroke.

Pipe expander should be equipped with a head suitable for the type of the pipe and its diameter. Insert the expanding head fully into the pipe until it stops, axially into the pipe end. Expansion of the pipe should be carried out in two phases: I – initial full expansion of the pipe, in full range of the tool stroke, turn the expander by 45° after expansion, II - final full expansion of the pipe, in full range of the tool stroke.

In temperatures lower than 5 °C, it is recommended to locally heat-up the pipe before expansion utilizing warm (max. 90 °C) air or water. The sliding sleeve must always be away from the expansion zone.

Directly (!) after expansion, insert the fitting into the pipe to the last protrusion on the fitting stub (do not push the pipe up to the fitting flange!). Do not use lubricants.

Directly (!) after expansion, insert the fitting into the pipe to the last protrusion on the fitting stub (do not push the pipe up to the fitting flange!). Do not use lubricants.

NOTE! If the pipe is excessively stretched, its material may build up during the connecting. In such a case, finish sliding the sleeve onto the pipe in front of fittings flange (keep a distance of max. 2 mm from the fitting flange).

NOTE! If the pipe is excessively stretched, its material may build up during the connecting. In such a case, finish sliding the sleeve onto the pipe in front of fittings flange (keep a distance of max. 2 mm from the fitting flange).

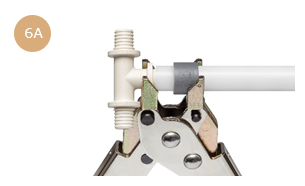

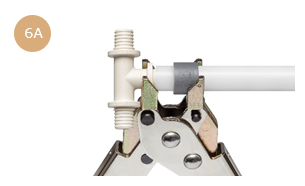

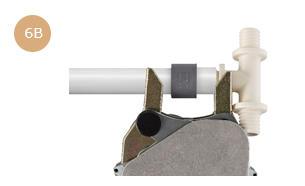

The press machine should be equipped with special forks. A separate set of forks is intended for each diameter. The forks are equipped with special bumpers protecting the fitting and the sleeve against damage due to excessive clamping force.

The press machine should be equipped with special forks. A separate set of forks is intended for each diameter. The forks are equipped with special bumpers protecting the fitting and the sleeve against damage due to excessive clamping force.

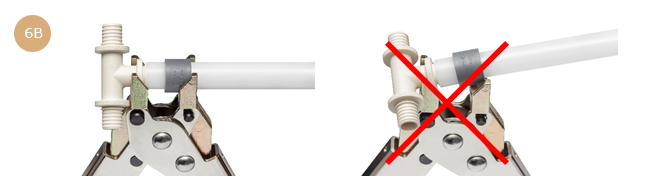

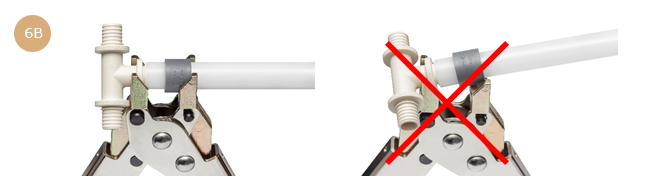

Slide the sleeve using manual chain press. The fittings may be caught only by their flanges. It is forbidden to slide on two sleeves at the same time.

Slide the sleeve using manual chain press. The fittings may be caught only by their flanges. It is forbidden to slide on two sleeves at the same time.

It is possible to slide on a sleeve with the use of electric drives, typical of “Press”” connections. The condition to use this type of tools for sliding the sleeve is the use of a special adapter provided by System KAN-therm ultraLINE.

It is possible to slide on a sleeve with the use of electric drives, typical of “Press”” connections. The condition to use this type of tools for sliding the sleeve is the use of a special adapter provided by System KAN-therm ultraLINE.

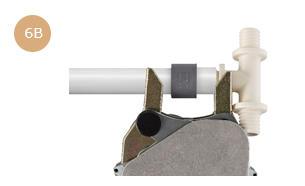

When sliding the sleeve onto the fitting, the assembly process should be observed – after the sleeve is pushed to the fitting flange, the sliding process should be stopped. The connection is ready for pressure testing.

When sliding the sleeve onto the fitting, the assembly process should be observed – after the sleeve is pushed to the fitting flange, the sliding process should be stopped. The connection is ready for pressure testing.

Connecting Technology

Basic method of connecting pipes in the System KAN-therm ultraLINE is the axial press technique utilizing PVDF plastic sliding sleeve. The connection is obtained by putting the extended end of the pipe onto the fitting stub and then sliding onto such connection plastic sleeve.

The material of the pipe is pressed into the connector's notches, owing to which the entire connector surface is sealed – it guarantees perfect tightness and durability of the system. This technique does not require any additional O-ring seals and the quick and easy assembly guarantees resistance to possible assembly errors.

The material of the pipe is pressed into the connector's notches, owing to which the entire connector surface is sealed – it guarantees perfect tightness and durability of the system. This technique does not require any additional O-ring seals and the quick and easy assembly guarantees resistance to possible assembly errors.

The selected pipe should be cut perpendicularly to the axis to the required length by means of plastic pipe cutters. It is not allowed to use other tools or scissors which are faulty (blunt or chipped).

The selected pipe should be cut perpendicularly to the axis to the required length by means of plastic pipe cutters. It is not allowed to use other tools or scissors which are faulty (blunt or chipped).

Put the sleeve onto the pipe. Symmetric structure allows for both-side installation.

Put the sleeve onto the pipe. Symmetric structure allows for both-side installation.

Pipe expander should be equipped with a head suitable for the type of the pipe and its diameter. Insert the expanding head fully into the pipe until it stops, axially into the pipe end. Expansion of the pipe should be carried out in two phases: I – initial full expansion of the pipe, in full range of the tool stroke, turn the expander by 45° after expansion, II - final full expansion of the pipe, in full range of the tool stroke.

Pipe expander should be equipped with a head suitable for the type of the pipe and its diameter. Insert the expanding head fully into the pipe until it stops, axially into the pipe end. Expansion of the pipe should be carried out in two phases: I – initial full expansion of the pipe, in full range of the tool stroke, turn the expander by 45° after expansion, II - final full expansion of the pipe, in full range of the tool stroke.In temperatures lower than 5 °C, it is recommended to locally heat-up the pipe before expansion utilizing warm (max. 90 °C) air or water. The sliding sleeve must always be away from the expansion zone.

Directly (!) after expansion, insert the fitting into the pipe to the last protrusion on the fitting stub (do not push the pipe up to the fitting flange!). Do not use lubricants.

Directly (!) after expansion, insert the fitting into the pipe to the last protrusion on the fitting stub (do not push the pipe up to the fitting flange!). Do not use lubricants. NOTE! If the pipe is excessively stretched, its material may build up during the connecting. In such a case, finish sliding the sleeve onto the pipe in front of fittings flange (keep a distance of max. 2 mm from the fitting flange).

NOTE! If the pipe is excessively stretched, its material may build up during the connecting. In such a case, finish sliding the sleeve onto the pipe in front of fittings flange (keep a distance of max. 2 mm from the fitting flange). The press machine should be equipped with special forks. A separate set of forks is intended for each diameter. The forks are equipped with special bumpers protecting the fitting and the sleeve against damage due to excessive clamping force.

The press machine should be equipped with special forks. A separate set of forks is intended for each diameter. The forks are equipped with special bumpers protecting the fitting and the sleeve against damage due to excessive clamping force.

Slide the sleeve using manual chain press. The fittings may be caught only by their flanges. It is forbidden to slide on two sleeves at the same time.

Slide the sleeve using manual chain press. The fittings may be caught only by their flanges. It is forbidden to slide on two sleeves at the same time.

It is possible to slide on a sleeve with the use of electric drives, typical of “Press”” connections. The condition to use this type of tools for sliding the sleeve is the use of a special adapter provided by System KAN-therm ultraLINE.

It is possible to slide on a sleeve with the use of electric drives, typical of “Press”” connections. The condition to use this type of tools for sliding the sleeve is the use of a special adapter provided by System KAN-therm ultraLINE.

When sliding the sleeve onto the fitting, the assembly process should be observed – after the sleeve is pushed to the fitting flange, the sliding process should be stopped. The connection is ready for pressure testing.

When sliding the sleeve onto the fitting, the assembly process should be observed – after the sleeve is pushed to the fitting flange, the sliding process should be stopped. The connection is ready for pressure testing.

Pay attention to correct position of the fittings in the forks of the tools. In the event of non-compliance with this rule, the fitting and the components of the connection may be overloaded.

Copyright © 2017 KAN Group | All rights reserved. Privacy policy and important information concerning cookies.