- Ponuka

- KAN-therm ultraLINE System

- System KAN-therm ultraPRESS

- System KAN-therm PP

- System KAN-therm Steel

- System KAN-therm Inox

- System KAN-therm Inox Sprinkler

- System KAN-therm Groove

- System KAN-therm Copper

- System KAN-therm Tacker

- System KAN-therm Profil

- System KAN-therm Rail

- System KAN-therm TBS

- Systém KAN-therm WALL – mokrá metoda Novinka!!!

- System KAN-therm WALL - сух метод Новост!!!

- System KAN-therm Football

- KAN-therm InoxFlow

- KAN-therm Slim & Slim+ skrinky

- Na stiahnutie

- Záruka kvality

- O nás

- O nás

- Filozofie firmy

- Výroba

- Events

- Noviny

- A new KAN production plant has opened!

- Newsletter coming out soon!

- SYSTEM KAN-therm at Aquatech China 2017

- Changes in the KAN-therm 6in1 System catalogue

- KAN-therm in Jordanki

- Ďakujeme za návštevu Aquatech China 2017

- Nové inštalačné skrinky SYSTÉMU KAN-therm

- Pozrite si naše nové návodné video aplikácie KAN Smart Control

- Slovenský katalóg je teraz k dispozícii!

- KAN-therm certified quality

- Amazon v Seredi

- Become Underfloor Heating KAN-therm System Champion

- Navštívte KAN-therm na ISH India

- Visit KAN at ISH Frankfurt 2019

- Skontrolujte riešenia KAN-therm pre rodinné domy

- System KAN-therm v salóne PORSCHE

- KAN-therm s novým certifikátom QB

- System KAN-therm Groove

- ZRM. Estetika ruka v ruke s funkčnosťou.

- Nové lisovačky v ponuke KAN-therm

- Montáž System KAN-therm Groove

- KAN-therm Multi-system

- Inštalácie...neoplatí sa šetriť na nich!

- Novinka – KAN Rozdeľovač z nerezovej ocele

- Aquatherm Praha 2020

- Správne bezpečnostné opatrenia, rovnaká účinnosť

- New products on offer

- History

- Noviny

- Fairs

- Kontakty

- Slovak / Slovak

-

- Belarusian | bieloruský

- Bosnian | bosnianska

- Bulgarian | bulharský

- Croatian | chorvátsky

- Czech | český

- English | anglicky

- Estonian | estónsky

- Finnish | fínsky

- French | francúzsky

- German | nemecký

- Hungarian | maďarský

- Latvian | lotyšský

- Lithuanian | litovský

- Polish | poľský

- Romanian | rumunský

- Russian | ruský

- Serbian | srbský

- Slovak | slovenský

- Slovenian | slovinčina

- Swedish | Švedsko

- Ukrainian | ukrajinský

- Norwegian | nórsky

- Belarusian | bieloruský

This method of groove preparation is possible with the use of small and mobile devices and thus, it makes it more popular. It is possible to prepare pipes at the very construction site. On the other hand, pipe grooving through machining requires usage of a slightly larger equipment and therefore it is most often performed in factory or specially prepared workshops at a construction site.

Pipes

The System KAN therm Groove couplings allows for connection of traditional carbon steel, black or galvanized pipes (diameters DN25-DN300)

| EN | European standard (metric system) |

| ISO | ISO standard (metric system) |

| BS | British standard (metric system) |

| DIN | German standard (metric system) |

| IPS | American standard (metric system) |

It must be ensured that the prepared pipe has an outside diameter (OD) and wall thickness applicable for the application. Due to the fact that the KAN-therm Groove couplings are usually identified according to the nominal dimension, the actual outer diameter (OD) of the pipe and the couplings connected to it must always be checked, as it is customary in some markets to relate different pipe diameters to the same nominal dimension.

Pipe dimension equivalents

| Dimension in inches | Dimension in millimetres | ||

| Nominal | Actual | Nominal | Actual |

| 1/2 | 0.840 | DN15 | 21.3 |

| 3/4 | 1.050 | DN20 | 26.7 |

| 1 | 1.315 | DN25 | 33.7 |

| 1 1/4 | 1.660 | DN32 | 42.4 |

| 1 1/2 | 1.900 | DN40 | 48.3 |

| 2 | 2.375 | DN50 | 60.3 |

| 2 1/2 | 2.875 | - | 73.0 |

| 3 OD | 3.000 | DN65 | 76.1 |

| 3 | 3.500 | DN80 | 88.9 |

| 3 1/2 | 4.000 | - | 101.6 |

| 4 1/4 OD | 4.250 | - | 108.0 |

| 4 | 4.500 | DN100 | 114.3 |

| 5 | 5.563 | - | 141.3 |

| 5 1/4 OD | 5.250 | - | 133.0 |

| 5 1/2 OD | 5.500 | DN125 | 139.7 |

| 6 1/4 OD | 6.250 | - | 159.0 |

| 6 | 6.625 | DN150 | 168.3 |

| 8 | 8.625 | DN200 | 219.1 |

| 10 | 10.750 | DN250 | 273.0 |

| 12 | 12.750 | DN300 | 323.9 |

System KAN-therm Groove Assembly

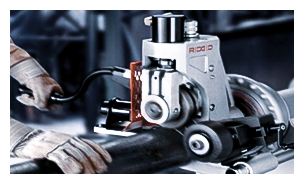

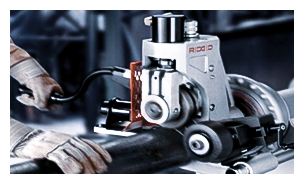

Before the assembly, pipes should undergo the proces of „grooving”. Grooving of pipes, for connections with KAN-therm Groove couplings, may be done utilizing two methods — through rolling or machining. Grooving through rolling is dedicated for pipes with a wall thickness of no more than 9.5 mm.This method of groove preparation is possible with the use of small and mobile devices and thus, it makes it more popular. It is possible to prepare pipes at the very construction site. On the other hand, pipe grooving through machining requires usage of a slightly larger equipment and therefore it is most often performed in factory or specially prepared workshops at a construction site.

Copyright © 2017 KAN Group | All rights reserved. Privacy policy and important information concerning cookies.