Najobľúbenejšie články na stránke

Najnovšie články

3 sep 2025

Palác Republiky (Krasińského palác), postavený v druhej polovici 17. storočia, je pravým klenotom varšavskej architektúry a jedným z najdôležitejších...

30 jún 2025

Zhrnutie: Prevádzka skupiny čerpadiel so stálou hodnotou – vysvetlenie Systém funguje na báze zmiešania vykurovacej vody zo zdroja tepla s vratnou vod...

4 jún 2025

Klimatické zmeny premenili zodpovednosť za životné prostredie z módneho sloganu na skutočnú výzvu, ktorá si vyžaduje konkrétne kroky. Každý rok sa na...

7 mája 2025

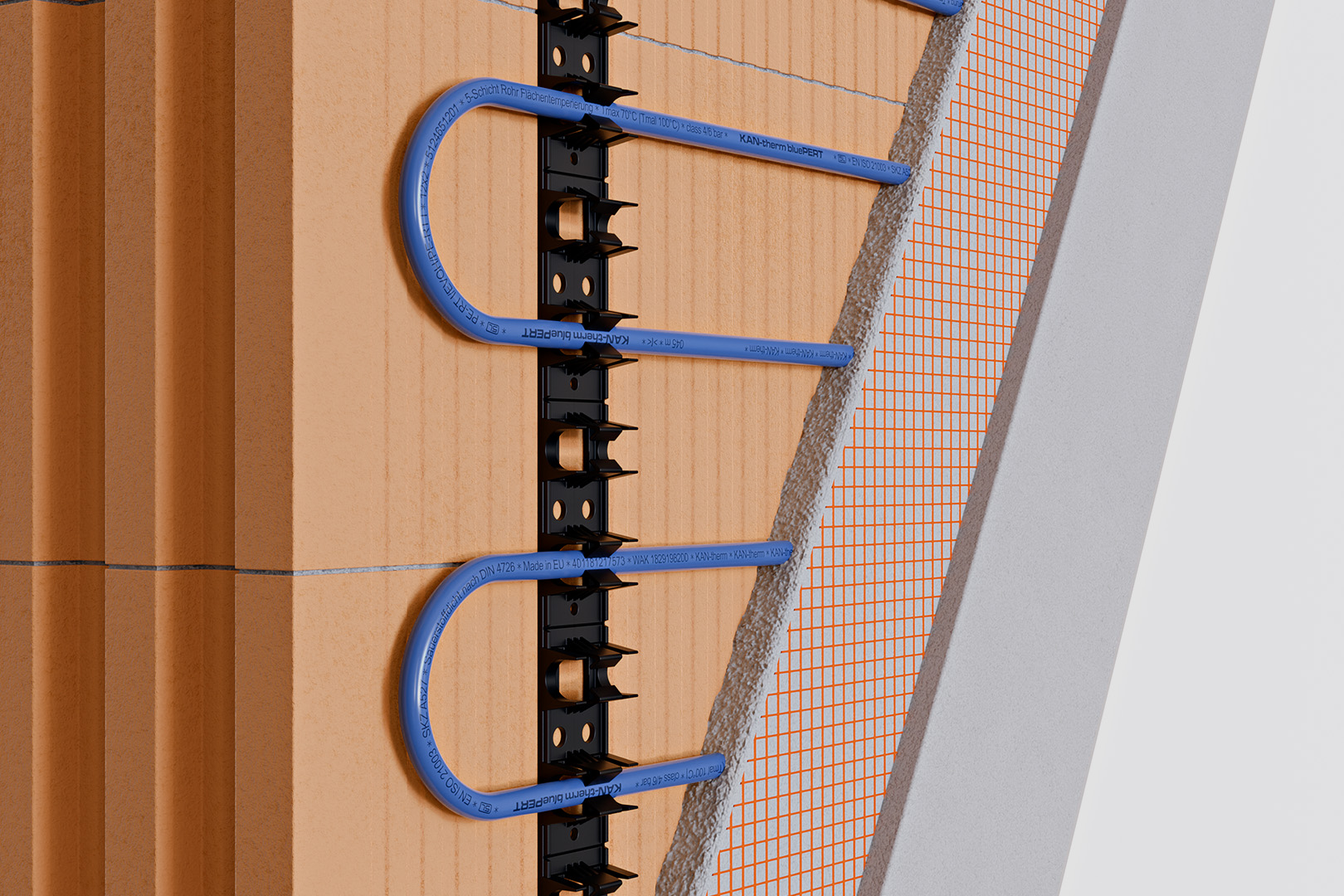

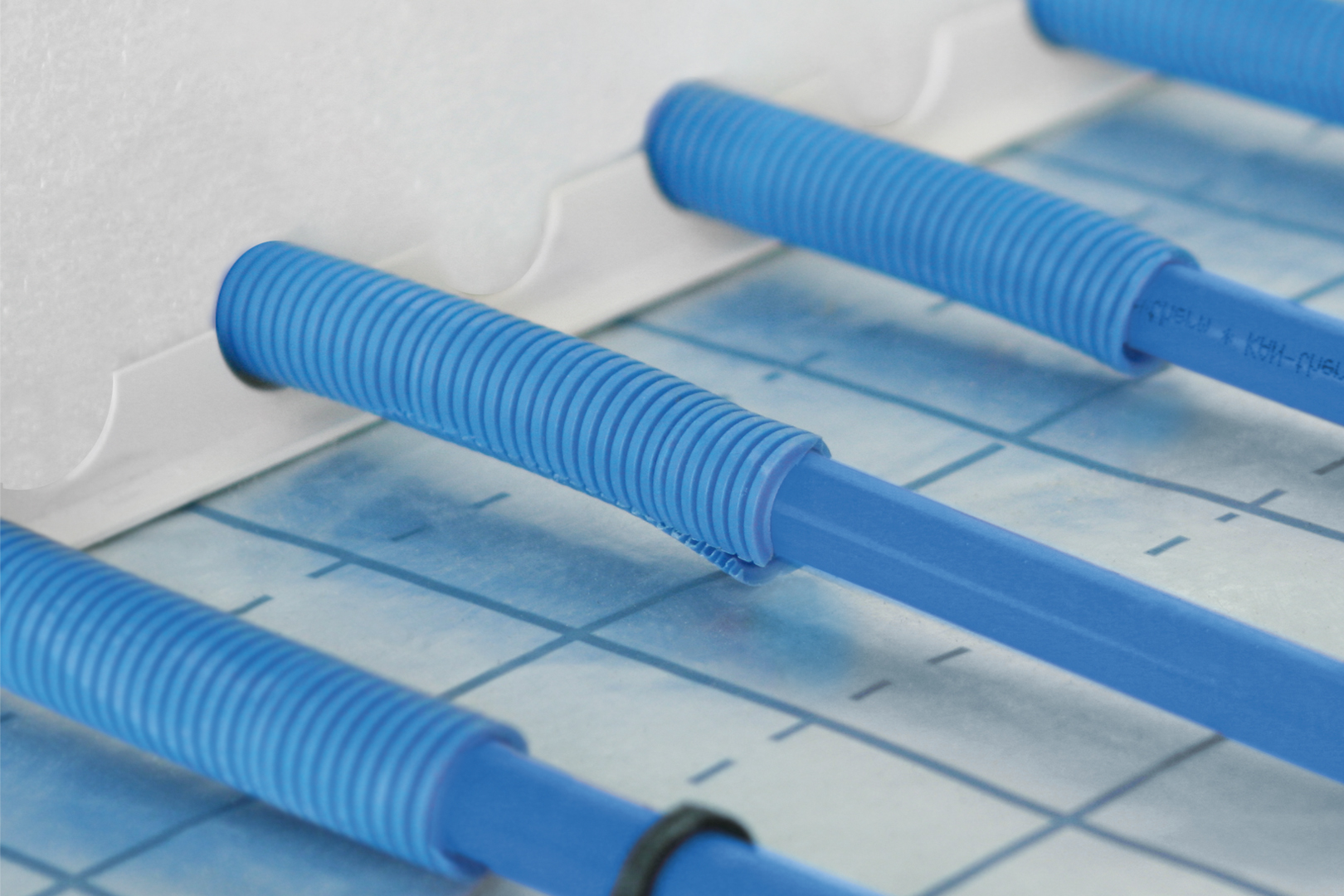

NOVINKY KAN SET povrchové systémy - stropný systém - stenový systém výpočet výsledného chladiaceho výkonu inštalácie V najn...

21 apr 2025

Riešenia dilatácie sa používajú na zabránenie negatívnym účinkom tepelnej rozťažnosti vykurovacích rúrok, ktoré podliehajú teplotným zmenám. Patria k...

30 jan 2025

Existujú dva spôsoby dezinfekcie vodovodnej siete: tepelná a chemická. Oba spôsoby by sa mali používať s maximálnou opatrnosťou. V tejto príručke vám...

5 dec 2024

Digitalizácia stavebných projektov je dnes už štandardným riešením. Aby spoločnosť KAN naplnila očakávania projektantov, svoje produkty pripravuje pod...

29 nov 2024

Uverejnili sme novú verziu aplikácie KAN SMART Control na správu automatizácie riadenia. Ak máte aplikáciu vo verzii 1.3.7 alebo staršej, určite navšt...

23 jún 2024

Vilnius je mesto plné nie príliš nápadných historických pamiatok, medzi ktoré patrí barokový palác rodu Sapiehovcov postavený koncom 17. storočia. V p...

20 jún 2024

Podlahové vykurovanie už nie je len luxusom, ale stáva sa každodenným štandardom pre pohodlné a zdravé bývanie. Uvádzame presvedčivé argumenty, prečo...

16 jún 2024

O podlahovém vytápění se v průběhu let vytvořilo mnoho mylných představ. Mnohé z těchto názorů totiž pramení z neznalosti nebo dezinformací a nezahrnu...

4 apr 2024

V éře trvale udržitelného rozvoje, kdy se stále větší pozornost věnuje funkčnosti a komfortu využívání prostor, se instalatéři, investoři a pronajímat...

8 mar 2024

Pred tridsiatimi rokmi sa v Prahe konal prvý ročník veľtrhu Aquatherm Praha 1994 a dnes sa, vďaka tomu, že sa pred desiatimi rokmi prešlo na jarnú sez...

8 mar 2024

V spoločnosti KAN sa vždy snažíme držať krok s najnovšími trendmi a technológiami v oblasti stavebných systémov. Tento rok sme mali zaujímavú príležit...

8 feb 2024

S potešením oznamujeme výsledok súťaže„Domáce kúpele budúcnosti v systéme KAN-therm“ pod heslom: „INŠTALUJ SVOJU VÍZIU“, ktorá sa usporiadala pri...

13 nov 2023

V súčasnosti je čoraz dôležitejšie uvedomelo a racionálne využívať naše prírodné zdroje, ako je napríklad voda, čo znamená udržateľné zaobchádzanie so...

5 nov 2023

Systém KAN-therm ultraPRESS je určený na vnútorné vodovodné rozvody (teplá a studená úžitková voda), ústredné vykurovanie a chladenie, procesné vedeni...

24 okt 2023

Systém KAN-therm ultraPRESS, známy svojou spoľahlivosťou a účinnosťou, je integrovanou súčasťou mnohých rôznych projektov na celom svete. Vďaka jednod...

10 okt 2023

Kľúčom k úspechu v oblasti vykurovacích a inštalačných technológií sa dnes stali inovácie. V reakcii na potreby a očakávania trhu zavádzame v novom ka...

28 júl 2023

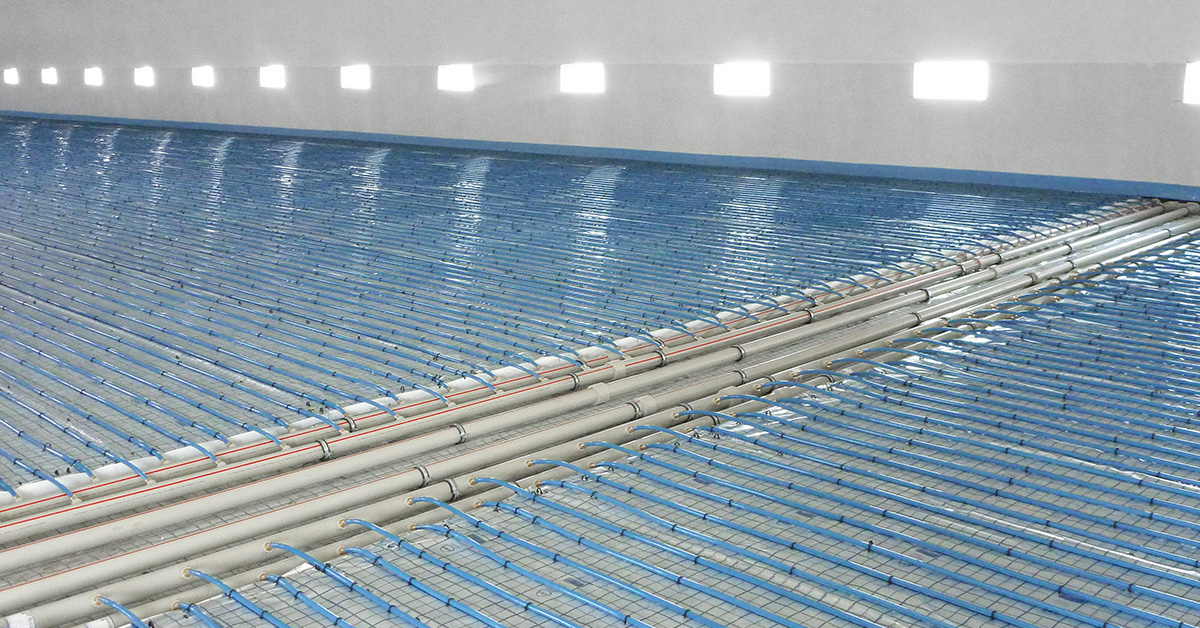

Systém KAN-therm v rastlinnej a chove zvierat Stabilná a primeraná teplota je jedným z najdôležitejších faktorov pre efektívny chov zvierat a rastlinn...

28 júl 2023

Podlahové vykurovanie je dnes štandardom, ktorý ponúkajú poprední svetoví developeri. Teplá podlaha pôsobí ako veľkoplošný radiátor, vďaka ktorému je...

14 mája 2023

Spoločnosť KAN-therm mala tú česť zúčastniť sa na veľtrhu Hungarotherm, ktorý sa konal v Budapešti od 29. marca do 2. apríla. Bola to skvelá príležito...